Gene therapy, a transformative approach in modern medicine, offers potential solutions for genetic diseases by introducing or modifying genetic material within patient cells. Central to this approach is the use of viral vectors, which are pivotal in delivering therapeutic genes to target cells. This article delves into the intricacies of viral vector production for gene therapy manufacturing.

Viral vectors: the cornerstone of gene therapy

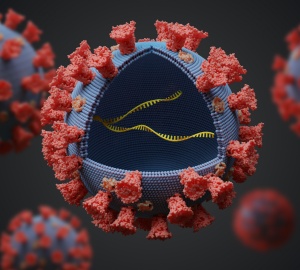

Viral vectors are modified viruses used to transport therapeutic genes into target cells. These vectors undergo rigorous modifications to negate their disease-causing potential while retaining their ability to infiltrate cells and transfer genetic material. Among the myriad of vectors, adeno-associated virus (AAV) and lentivirus have emerged as the prominent choices in gene therapy, spearheading the non-integrating and integrating groups of viral vectors respectively. As suggested by their name, integrating viral vectors work to integrate into the genome of target cells, where-as non-integrating vectors remain in the target cytoplasm in an episomal form. Integrating vectors displaying great promise in providing long-term treatment - particularly in target cells giving rise to large progeny as their therapeutic effects persist across proliferative generations.

The intricacies of viral vector production

The production of viral vectors is a multifaceted process, demanding precision at every step:

- Cell culture: Specific producer cell lines are cultivated using advanced cell culture techniques. These cell lines form the foundation for the subsequent stages of viral vector production.

- DNA transfection: Leveraging high-quality transfection reagents, the producer cells undergo transient DNA transfection. This critical step ensures high transfection efficiency, introducing the necessary nucleic acids into the host cell.

- Viral production: Following transfection, the cells initiate the viral production phase. The efficiency of this process is paramount, determining the overall yield and quality of the vector.

- Purification and formulation: Once produced, the vectors undergo downstream processes, ensuring their purification from potential contaminants. This step is crucial to guarantee the safety and efficacy of the vectors for therapeutic use.

Lentivirus in viral vector production

Lentivirus, a type of retrovirus, holds significant promise in gene therapy. Its ability to integrate its genetic material into the host cell genome ensures long-term therapeutic effects. The production of lentivirus vectors involves a methodical approach, from selecting appropriate cell lines to optimising transfection conditions using specialised transfection reagents.

Challenges and advancements in viral vector production

While viral vector production has seen considerable advancements, challenges persist. Achieving high throughput in large-scale production, ensuring consistent yields, and navigating the complexities of different cell types are areas of ongoing research. Moreover, the patient's immune system's potential response to the viral vector remains a concern, necessitating further exploration.

At Cambridge Bioscience, we understand the complexities and nuances of viral vector production. Our state-of-the-art kits & transfection reagents for viral vector production, tailored for AAV and lentivirus workflows, are designed to assist researchers in navigating the challenges of this intricate process. We invite the scientific community to explore our offerings, ensuring a collaborative approach towards advancing gene therapy. Catch up on the Mirus webinar to learn more about the role that LV and AAV transfection platforms play in gene therapy manufacturing.

To summarise: viral vector production stands as a linchpin in the realm of gene therapy. While challenges remain, the continuous advancements and collaborative efforts of the scientific community promise a brighter future for patients worldwide.

References and further reading

- Merten, O., Schweizer, M., Chahal, P.S., & Kamen, A.A. (2014). Manufacturing of viral vectors for gene therapy: part I. Upstream processing. Pharmaceutical bioprocessing, 2, 183-203.

- Peixoto, C., & Merten, O. (2021). Biomanufacturing of Gene Therapy Vectors. Biotechnology Journal, 16.

- Kopp, L., Larimore, B., Sutherland, N., & Dasgupta, A. (2021). CELL & GENE THERAPY INSIGHTS Key considerations for maximizing LV and AAV production in transient transfection workflows UPSTREAM BIOPROCESSING.